Latest version:

7.83.998

Latest version:

7.83.998

Curved surfaces (spherical or cylindrical), covered by thin overlayers, are frequently occurred and applied in the practice of surface analysis. Examples may include intentionally coated or contaminated powders, like catalysts, paint fillers, ceramic precursors, etc. and wires, coated or surface treated fibres for reinforcement of composites, etc.

Equations for calculation of the XPS intensity from layers on planar surfaces are widely known. The thicknesses of the layers are derived by fitting the measured and calculated intensity values for the selected lines of all constituent elements in both the layers and the underlying bulk. Applying this planar approach to curved surfaces, however, leading to overestimated layer thickness values.

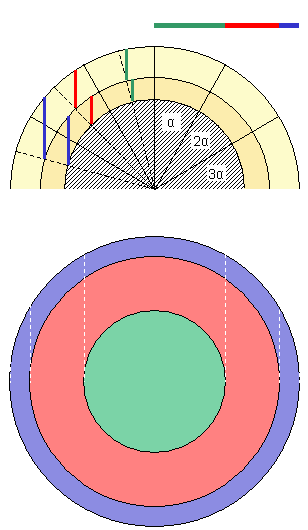

When the measured sample is not planar, the effective thickness of the layers (the effective thickness seen from the direction of electron analyser) is varying from point to point along the surface, showing a steep increase at high angles of elevation. The way of the calculation of photoelectron intensity emerging from curved surfaces covered by overlayers is similar to the calculation of planar samples, except that the areas with different effective layer thickness values should be calculated separately and should be weighted by a geometry correction factor (G1, G2, etc.), taking into account the projected areas corresponding to different thickness.

The geometry correction factors for spherical and cylindrical surfaces were derived by applying pure geometric considerations.

These types of calculations can be conveniently performed by XPS MultiQuant. The geometry correction factors, together with other necessary parameters, are included into the library of the program.